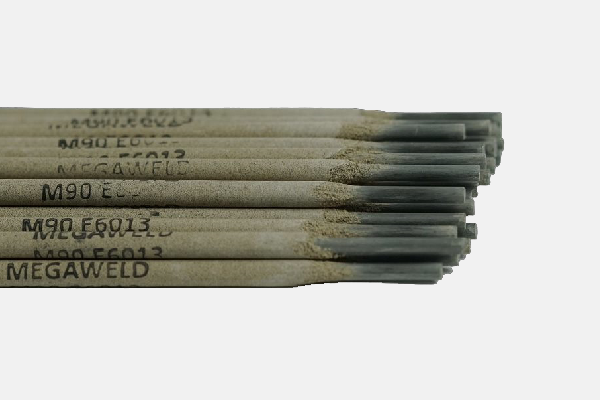

M-90 E6013

Features

Features

- Suitable for butt and fillet welding of thin plates

- Good restriking

- Good bead appearance

- Easy to remove slag

- Smooth arc and low fume

- AC welding with low OCV

Application

Welding of general low carbon steel.

- Coating Type: Rutile

- Welding Current: DC-, AC

- Welding Positions: All, besides vertical down

Classification

AWS/A5.1/ASME SFA5.1 E6013

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.05 | 0.23 | 0.35 | 0.022 | 0.017 | - | - | - |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| 439 (63,700) | 488 (70,900) | 26.8 | 0 (32) | 67 (50) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2 | 2.5 | 3.2 | 4 | 5 |

| LENGTH (mm) | 300 | 300 | 300 | 350 | 350 | 400 |

| CURRENT (amps) | 50-70 | 55-70 | 50-90 | 80-120 | 100-160 | 120-220 |

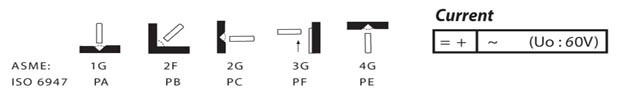

Current

AC or DC +

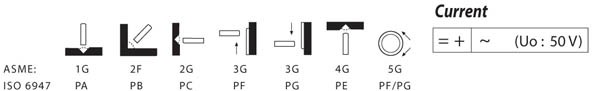

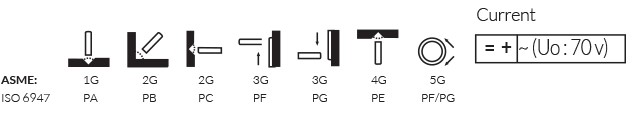

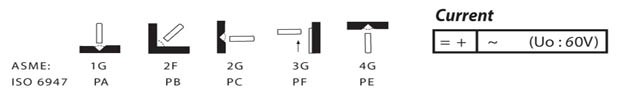

Welding Positions

M-90 E6012

Features

- Offer excellent bridging characteristics

- Good stable arc and operates at high current with low spatter

- Can be used with both ac and dc power

Application

Farm Implements, General Repair, Machinery Fabrication, Metal

Furniture, Ornamental Iron, Sheet Metal, Tanks

Classification

AWS/A5.1/ASME SFA5.1 E6012

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.05 | 0.23 | 0.35 | 0.022 | 0.017 | - | - | - |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| 436 (63,300) | 488 (71,000) | 26.9 | 0 (32) | 98 (73) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2 | 2.5 | 3.2 | 4 | 5 |

| LENGTH (mm) | 300 | 300 | 300 | 350 | 350 | 400 |

| CURRENT (amps) | 50-70 | 55-70 | 50-90 | 80-120 | 100-160 | 120-220 |

Current

AC or DC +

Welding Positions

M-90 E6011

Features

Features

- Standard in the pipe welding industry

- Deep penetration

- High ductility (root pass)

- AC and DC welding

Application

- Pipeline

- General fabrication

- Shipbuilding

Classification

AWS/A5.1/ASME SFA5.1 E6011

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.11 | 0.16 | 0.51 | 0.15 | 0.012 | - | - | - |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| 468 (68,000) | 588 (81,000) | 29.7 | -30 (-22) | 51 (38) |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 | 4 |

| LENGTH (mm) | 350 | 350 | 350 |

| CURRENT (amps) | 50-70 | 75-120 | 90-160 |

Current

AC or DC +

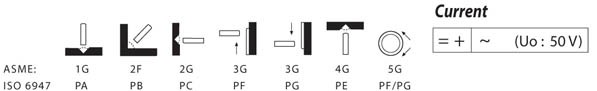

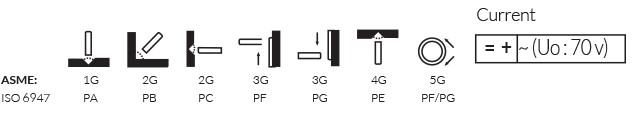

Welding Positions

M-90 E7018

Features

Features

- Suitable for butt and fillet welding of heavy structure

- Good crack resistance and x-ray performance

- Good mechanical properties

- Iron powder and low hydrogen type electrode (high efficiency)

Application

- Pressure vessel

- Heavy steel fabrication

- Shipbuilding

Classification

AWS/A5.1/ASME SFA5.1 E7018

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.06 | 0.5 | 1.2 | 0.017 | 0.011 | - | - | - |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| 504 (73,200) | 572 (83,100) | 29.8 | -30 (-22) | 111 (82) |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 | 4 |

| LENGTH (mm) | 350 | 350 | 400 |

| CURRENT (amps) | 55-85 | 90-130 | 130-180 |

Current

AC or DC +

Welding Positions

M-90 E7016

Features

- Suitable for butt and fillet welding of heavy structure

- Good crack resistance and x-ray performance

- Good mechanical properties

- Low fume

Application

- Heavy steel fabrication

- Shipbuilding

- Pressure vessel

Classification

AWS/A5.1/ASME SFA5.1 E7016

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.08 | 0.62 | 1.22 | 0.16 | 0.11 | - | - | - |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| 560 (81,300) | 641 (93,100) | 28.4 | -30 (-22) | 80 (59) |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 | 4 |

| LENGTH (mm) | 350 | 350 | 400 |

| CURRENT (amps) | 55-85 | 90-130 | 130-180 |

Current

AC or DC +

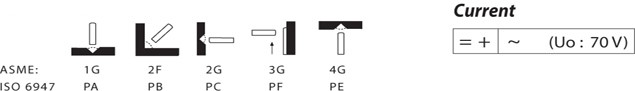

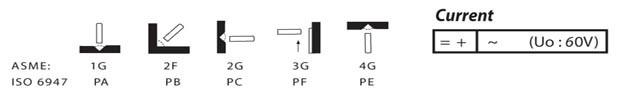

Welding Positions

M-90 E308

Features

- Good creep resistance

- Service temperature up to 350⁰c

- Easy to remove slag

- Low spatter

- Good bead appearance

Application

- Rutile-basic all position stainless steel electrode. Used for welding low-carbon stainless steels of the type AISI 304 in cases where maximum resistance to intergranular corrosion is required.

- For welding Titanium and Niobium stabilized stainless steels. Weld able on both AC and DC.

Classification

AWS/A5.4/ ASME SFA5.4 E308-16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.05 | 0.80 | 1.0 | 0.03 | 0.029 | 20.0 | 9.9 | 2.5 |

Mechanical Properties

| Y.S | T.S | EL | Temp. | CVN-Impact Value |

| N/mm2 (lbs/in 2) | N/mm2 (lbs/in 2) | (%) | oC (oF) | J (ft lbs) |

| 576 (83,500) | 576 (83,500) | 49.8 | -196 (-321) | 36 (27) |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2 | 2.5 | 3.2 | 4 | 5 |

| LENGTH (mm) | 300 | 300 | 350 | 350 | 350 | 350 |

| CURRENT (amps) | 20-55 | 25-55 | 50-85 | 70-110 | 95-145 | 135-190 |

Current

AC or DC +-

Welding Positions

M-90 E308L

Features

- Good resistance to corrosion and oxidizing environments

- Easy to remove slag

- Good bead appearance

- High moisture resistance (17type)

Application

- Rutile-basic coated electrode for welding non stabilized and stabilized corrosion resistant austenitic Cr-Ni steels up to 350°C.

- Smooth metal transfer with both AC and DC. Weld metal beads exhibit fine ripple formation.

- Focused and stable arc with low spatter loss.

- Self-detaching slag.

- Moisture resistant formulation producing welds free from porosity.

Classification

A5.4/ ASME SFA5.4 E308L-16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.02 | 0.80 | 0.75 | 0.03 | 0.029 | 18.9 | 9.9 | 2.5 |

Mechanical Properties

| Y.S | EL |

| N/mm2 (lbs/in 2) | (%) |

| 562 (81,600) | 47 |

Welding Parameters

| DIAMETER (mm) | 1.6 | 2 | 2.5 | 3.2 | 4 | 5 |

| LENGTH (mm) | 300 | 300 | 350 | 350 | 350 | 350 |

| CURRENT (amps) | 20-55 | 25-55 | 50-85 | 70-110 | 95-145 | 135-190 |

Current

AC or DC +-

Welding Positions

M-90 E309

Features

- Good resistance to heat and corrosion

- Easy to remove slag

- Low spatter

Application

- Rutile-basic coated low carbon all positions stainless steel electrode.

- Suitable for welding high alloyed corrosion resistant Cr-Ni-Mo steels, dissimilar steels (austenitic to ferritic steels). Deposition of austenitic cladding root runs.

- Focused and stable arc.

- Easy slag release.

Classification

A5.4/ ASME SFA5.4 E309.16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.03 | 0.79 | 1.1 | 0.025 | 0.016 | 23.4 | 12.5 | 0.1 |

Mechanical Properties

| T.S | EL |

| N/mm2 (lbs/in 2 ) | (%) |

| 579 (84,100) | 38.6 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 |

| LENGTH (mm) | 350 | 350 |

| CURRENT (amps) | 50-85 | 70-100 |

Current

AC or DC +-

Welding Positions

M-90 E310

Features

- Good heat resistance

- Good mechanical properties

- Martensite structure (all-weld metal)

- Easy to remove slag

Application

- Basic rutile coated, fully austenitic all position electrodes.

- Suitable for welding heat resistant Cr and Cr-Ni steels.

- Oxidation and scaling resistance up to 1200°C

Classification

A5.4/ ASME SFA5.4 E310.16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.10 | 0.6 | 1.9 | 0.018 | 0.013 | 26.5 | 20.6 | - |

Mechanical Properties

| T.S | EL |

| N/mm2 (lbs/in 2 ) | (%) |

| 610 (88,400) | 35 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 |

| LENGTH (mm) | 350 | 350 |

| CURRENT (amps) | 50-85 | 70-100 |

Current

AC or DC +-

Welding Positions

M-90 E312

Features

- Good crack resistance

- Good mechanical properties

- Easy to remove slag

Application

- Buffer layer for build up

- Welding dissimilar steels

Classification

A5.4/ ASME SFA5.4 E312.16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.10 | 0.45 | 1.4 | 0.018 | 0.013 | 28.5 | 9.6 | - |

Mechanical Properties

| T.S | EL |

| N/mm2 (lbs/in 2 ) | (%) |

| 803 (116,600) | 22.0 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 |

| LENGTH (mm) | 300 | 350 |

| CURRENT (amps) | 45-80 | 65-110 |

Current

AC or DC +-

Welding Positions

M-90 E316

Features

- Good resistance to corrosion and oxidizing environments

- Good heat resistance

- Asy to remove slag

- Low spatter

Application

- High recovery (170%) rutile coated electrode for welding austenitic stainless cr-ni-mo steels.

- Used whenever easy welding, smooth welding surfaces and a high deposition rates are required.

Classification

A5.4/ ASME SFA5.4 E316-16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.03 | 0.77 | 0.9 | 0.03 | 0.029 | 18.7 | 12.3 | 2.5 |

Mechanical Properties

| T.S | EL |

| N/mm2 (lbs/in 2 ) | (%) |

| 572 (83,100) | 40.8 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 |

| LENGTH (mm) | 350 | 350 |

| CURRENT (amps) | 50-85 | 70-100 |

Current

AC or DC +-

Welding Positions

M-90 E316L

Features

- Good resistance to corrosion and oxidizing environments

- Good heat resistance

- Easy to remove flag

- High moisture resistance (17type)

Application

- Rutile coated electrode for welding on stabilized corrosion resistant Cr-Ni-Mo steels.

- Smooth metal transfer with both AC and DC.

- Weld metal beads exhibit fine ripple formation.

- Focused and stable arc with low spatter loss.

- Easy slag release.

- Moisture resistant formula producing welds free from porosity.

Classification

A5.4/ ASME SFA5.4 E316L-16

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.025 | 0.80 | 0.80 | 0.03 | 0.29 | 18.7 | 11.3 | 2.5 |

Mechanical Properties

| T.S | EL |

| N/mm2 (lbs/in 2 ) | (%) |

| 572 (83,100) | 40.8 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 |

| LENGTH (mm) | 350 | 350 |

| CURRENT (amps) | 50-85 | 70-100 |

Current

AC or DC +-

Welding Positions

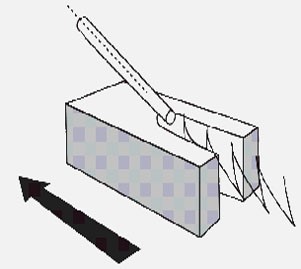

M-90 Arc Force

Features

- Chamfer rod for gouging and cutting is great for gouging our welds, removing unwanted metals, and veeing out cracks in catings (steel, cast iron,etc.) works on both ferrous application. Fast gouging and piercing.

Application

- Hold electrode in the direction of the desired groove.

- use the shortest arc possible.

- position electrode at a low angle to the work piece (10⁰ to 15⁰).

Classification

GOUGING-PIERCING-BEVELING

Chemical Compositions

| C | Si | Mn | P | S | CR | Ni | MO |

| 0.10 | 0.37 | 0.49 | 0.017 | 0.009 | 0.89 | - | - |

Welding Parameters

| DIAMETER (mm) | 3.2 |

| LENGTH (mm) | 350 |

| CURRENT (amps) | 100-150 |

Current

AC or DC

Welding Positions

M-90 E4043

Features

Features

- Good stable arc

- Operates at low temperatures

- Low spatter and fume

Application

- General Purpose Aluminum

- Good at heat treatment Aluminum parts

- Can be use in brazing

Classification

AWS / ASME SFA5.3 E4043

Chemical Compositions

| Al | Si | Fe | Cu | S | CR | Ni | MO |

| BAL. | 4.5-6.0 | 0.6 | 0.2 | - | - | - | - |

Mechanical Properties

| T.S | Cold corner piece |

| MPa | (d-2t) |

| 130 | 150 |

Welding Parameters

| DIAMETER (mm) | 1.6 | 3.2 | - |

| LENGTH (mm) | - | 350 | - |

| CURRENT (amps) | - | 70-100 | - |

M-90 E5356

Features

Features

- Best for color matching after anodizing

- With magnesium

- Operates at low temperatures

- Low spatter and fume

Application

- General Purpose Aluminum

- Good at heat treatment Aluminum parts

- Can be use in brazing

Classification

AWS / ASME SFA5.3 E5356

Chemical Compositions

| Y.S | T.S | EL | |

| MPa | MPa | (%) | |

| 117 | 268 | 17 | 0 (32) |

Mechanical Properties

| Al | Si | Fe | Cu | Mg | CR | Ni | MO |

| BAL. | 0.15 | 0.6 | 0.04 | 4.5-5.5 | - | - | - |

Welding Parameters

| DIAMETER (mm) | 1.6 | 3.2 | - |

| LENGTH (mm) | - | 350 | - |

| CURRENT (amps) | - | 70-100 | - |

M-90 E1100

Features

Features

- Pure aluminum

- Salt type coating

- Fast short arc welding

Application

- Welding of pure aluminum

- Corrosion resistance

- Have good strength

Classification

AWS / ASME SFA5.3 E1100

Chemical Compositions

| Al | Si | Fe | Cu | Mg | CR | Ni | MO |

| 99 | 4.5-6.0 | 0.6 | 0.2 | 4.5-5.5 | - | - | - |

Mechanical Properties

| T.S | Y.S |

| MPa | MPa |

| 70 | 55 |

Welding Parameters

| DIAMETER (mm) | 1.6 | 3.2 | - |

| LENGTH (mm) | - | 350 | - |

| CURRENT (amps) | - | 70-100 | - |

M-90 ENi-CI

Features

Features

- High-strength arc-submerge welding wires in series

- High-strength copper-plating

- Common electrodes

Application

- Special electrode for depositing soft machinable metal on grey cast iron.

- Excellent for repairing casting defects in grey cast iron.

- Can join cast irons to steels, monels etc.

Classification

A5.15/ ASME SFA5.15 Eni-CI

Chemical Compositions

| C | Si | Mn | P | S | Fe | Ni | MO |

| 1.35 | 0.78 | 0.35 | 0.004 | 0.003 | 0.55 | 96.0 | - |

Hardness

| Hardness (HRB) |

| 77 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 | 4 |

| LENGTH (mm) | 350 | 350 | 350 |

| CURRENT (amps) | 55-80 | 80-110 | 90-135 |

Current

AC or DC +-

Welding Positions

M-90 ENife-CI

Features

Features

- High impact toughness as low temperature

- Good arc & slag stability and hot cracking resistance

- Good productivity

Application

- Basic coated electrode which deposits a machinable nickel iron alloy weld.

- Designed for strength welding of high duty cast iron such as mechanite, malleable and spheroidal graphite and nodular irons.

- Welds high phosphorus castings.

- Typical components to be welded are machine bases, pump bodies, engine blocks, gears and transmission housings.

Classification

A5.15/ ASME SFA5.15 ENiFe-CI

Chemical Compositions

| C | Si | Mn | P | S | Fe | Ni | MO |

| 1.73 | 0.59 | 1.35 | 0.005 | 0.001 | 45.7 | 55.00 | - |

Hardness

| Hardness (HRB) |

| 90.0 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 | 4 |

| LENGTH (mm) | 350 | 350 | 350 |

| CURRENT (amps) | 60-90 | 80-130 | 110-160 |

Current

AC or DC +-

Welding Positions

M-90 ESt

Features

Features

- Shielded metal arc welding of cast iron metal

- Non-machinable

- Semi machinable and non machinable types

Application

- Repairing of cast iron.

Classification

A5.15/ ASME SFA5.15 ESt

Chemical Compositions

| C | Si | Mn | P | S | CR | Fe | MO |

| 2.47 | 0.41 | 0.45 | 0.024 | 0.024 | 0.0 | 97.6 | - |

Hardness

| Hardness (HRB) |

| 450-510 |

Welding Parameters

| DIAMETER (mm) | 2.5 | 3.2 | 4 |

| LENGTH (mm) | 350 | 350 | 350 |

| CURRENT (amps) | 60-90 | 80-130 | 110-160 |

Current

AC or DC +-